Water board Aa en Maas ensures safe, clean water for the eastern section of the Dutch province of Brabant. Among other things, this involves the daily purification of 300 million litres of water. To achieve this, the water board also manages over 400 kilometres of pipelines.

Performing a comprehensive condition assessment to investigate possible degradation of two asbestos cement pipes without excavation or demolition work.

With our Acquarius inspection tool we were able to assess the condition, while both pipelines remained in operation. Inspection data allowed us to estimate the replacement investment.

Water board Aa en Maas manages dozens of kilometres of asbestos cement (AC) pipelines. The majority of the pipework was laid in the 1970s and ’80s and is now nearing the end of its lifetime. Moreover, such pipelines are vulnerable to leaching and therefore, pipe breaches. The water board wants to assess the condition of its network in order to determine the required investment for replacement. The Acquarius inspection tool plays an important role.

It’s difficult for water boards to gain proper insight into the condition of AC pipelines. Fred Bergman is responsible for the maintenance of pipelines and civil engineering structures at Water board Aa en Maas and knows this all too well. ‘Current methods to pipeline condition assessments are often destructive and relatively imprecise. We do inspection using cameras, for example, but that doesn’t always give us enough information. Radar inspections only measure a few spots along a route. Furthermore, we also have to dig at those locations.

Water board Aa en Maas invests in new pipeline inspection methods and techniques for more insight into its network. Bergman: ‘We have a real need for inspection tools that can allow us to assess pipelines quickly and accurately (without excavation or demolition work). This is why we’ve been working with Acquaint for several years now. To further develop the Acquarius technique, among other things. We have already performed multiple condition assessments with Acquaint.’

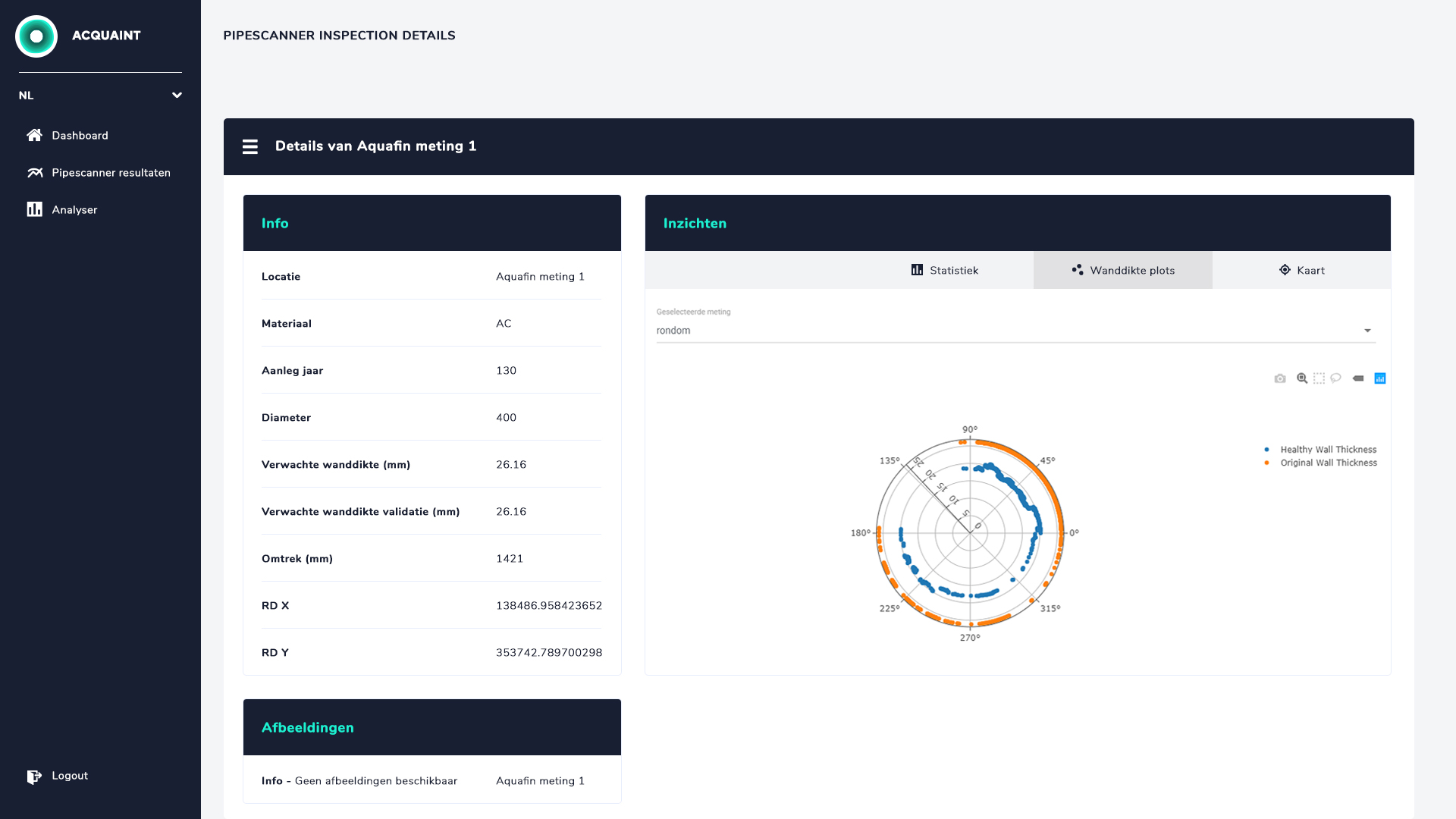

Two recent inspections using the Acquarius took place in 2020. These involved two comparable asbestos cement pressure pipelines from the nineteen-seventies. One is located at Nuland, the other at Geffen. Both pipelines have an internal diameter of 250 mm and are over two kilometres in length. Bergman: ‘The aim of the inspections is to determine the pipeline quality, leaching, wall thickness and location. We also want to detect any defects such as dents, ovality, gap width, angular displacement, poor joints and leakages.’

One of the Acquarius’s major benefits is the ability to perform an inspection while the pipeline is in operation.

One of the Acquarius’s major benefits is the ability to perform an inspection while the pipeline is in operation. To ‘launch’ the inspection tool, a Pig Trap is placed on a T or Y-piece. Once inside the pipeline, the Acquarius is pushed forward by water pressure. The Acquarius made its way through the Nuland and Geffen transport pipelines, was received by the trap at the pumping station there and then lifted out by a crane.

The Acquarius produced a full inline condition assessment of both pipelines. The inspection resulted in a report that gave an accurate picture of the pipeline condition and also identified any risks. The water board’s pipeline data (year/location/wall thickness/supplier) can be used to determine whether any angular displacement or gap width is exceeding the supplier’s prescribed tolerances. Or if there is presence of leaching (through highly accurate ultrasonic inspection) or deterioration in the pipelines due to H2S, signs of reduced wall thickness.

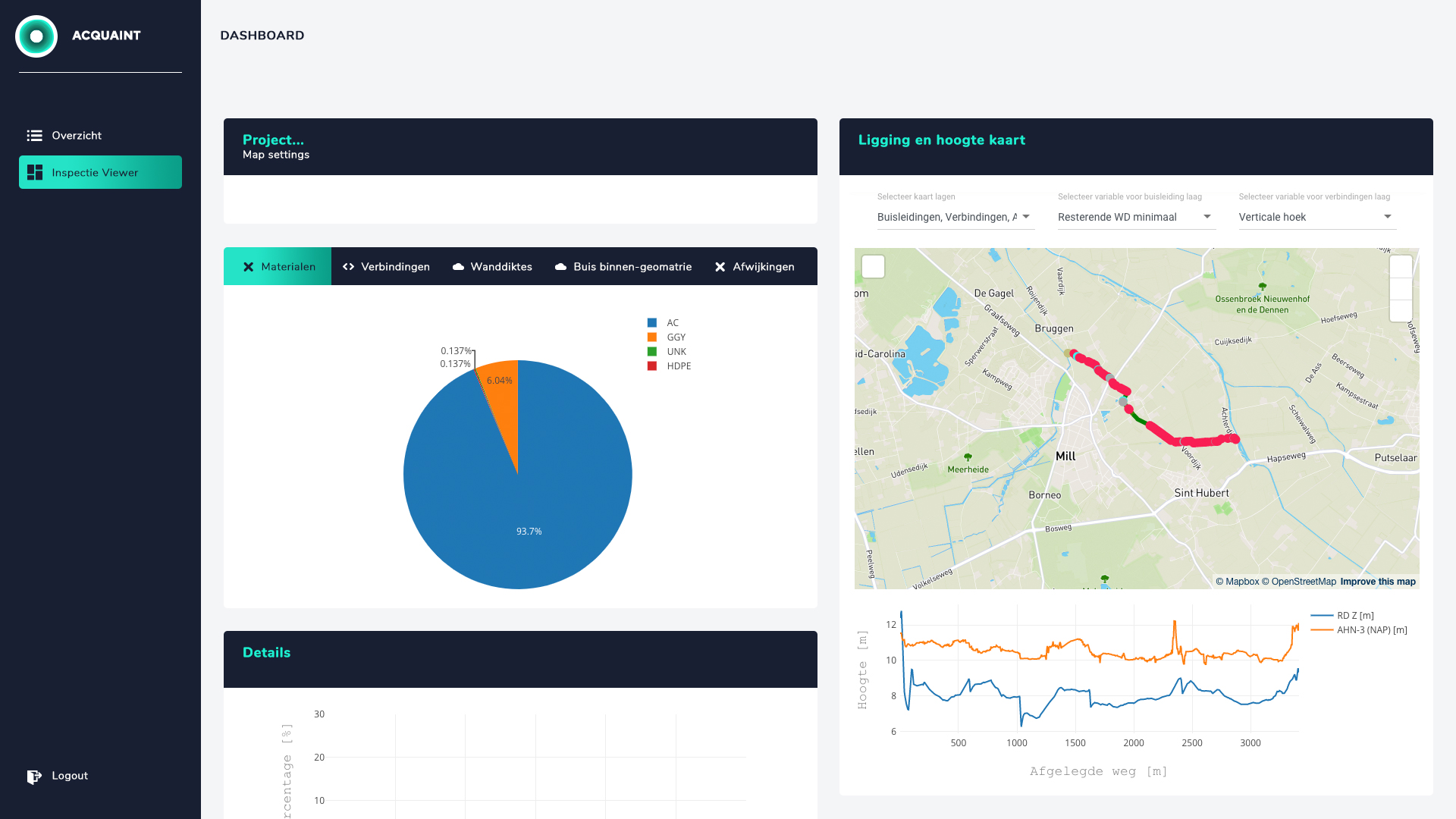

An online dashboard provides access to the reports and insights. In the course of two years, these analyses and reports have gradually improved, step by step. Bergman: ‘Reading all the data was a challenge in the beginning, especially because everything was tracked through different programs. In the meantime, all the data is collected in one environment. A single mouse click is enough to display specific data and then generate various reports. The dashboard also contains an overview of the locations that are in need of attention.’

The Geffen pipeline inspection demonstrated the analyses’ degree of accuracy. The report for this pipeline section was available in early March. This revealed the presence of a distinct angular displacement at a certain location; a potential risk. Less than two days after the report was in, a breach occurred at that exact spot. Bergman: ‘The data was clear, as were the recommendations. However, we were overtaken by events before we managed to do anything. The repair revealed that there was in fact significant angular displacement in one of the collars. This had generated so much tension that the pipe behind it cracked.’

This incident was an exception, by the way. Bergman: ‘The pipelines that we have inspected with the Acquarius in the past few years haven’t revealed anything too shocking. There are various action points, of course, but no major sections in need of replacement. The pipelines are generally in a good condition, and that’s reassuring to know. Without the Acquarius we would probably have dug up many more pipelines for inspection. Now we know that won’t be necessary. This is what makes the investment in the Acquarius so worthwhile.’

Bergman: ‘Normally we inspect our pipelines every ten to fifteen years, depending on their condition. With this new method, we can move up the next inspection by another ten years. We’ve therefore decided to commit to longer-term plans. The crux of the matter: how will it affect our budget to perform targeted inspections, followed by targeted repairs or replacement, instead of replacing pipelines entirely?’

Bergman: ‘More than one party is working on the development of inspection methods and techniques, of course; it would be fantastic if we could pool our knowledge. Our collaboration with Acquaint has been very satisfactory. We collaborate smoothly and the data is excellent. Naturally we pose critical questions to keep one another on our toes. The inspections generate lots of valuable data (and potential cost savings), freeing up the budget to continue this collaboration.’