Water Board Limburg (WBL) purifies the wastewater of Limburg so that it can be discharged into the surface water responsibly. WBL manages 540 kilometres of waste water transport pipelines in total.

To gain insight into the current technical state of the existing pipelines, in order to draw up a good maintenance plan and to map out the replacement task.

Using the Acquarius inspection tool of Acquaint, the condition of the existing pressure pipelines is mapped in one run.

Water Board Limburg (WBL) manages 540 kilometres of wastewater transport pipelines in the province of Limburg, the Netherlands. The pipeline materials used, vary greatly. Many of these pipelines have since been economically written off. However, this does not mean that the maximum technical lifespan has been reached. For this reason, WBL would like to gain insight into the current technical state of especially the asbestos cement and concrete pressure pipelines.

For WBL, it was especially important to know what the maintenance plan and the replacement task would look like in the coming years. On what and how much needs to be invested? And which area has priority now? With these questions in mind, WBL approached Acquaint.

Frank Verkuijlen is Senior Advisor in Asset Management at WBL. He explains: ‘If we don’t have insight into the current condition of our pipes, there is no reliable information available for the replacement task in both the medium and long term. We have a total of 540 kilometres of pipelines. Based on their economic life, a large proportion of them would have to be replaced. This can and must, of course, be done much more efficiently and reliably. For example, we recently assumed that ten kilometres of pipeline would be in very poor condition. The cost of replacing this entire stretch is about a million euros per kilometre. A quick calculation shows that we would then have to invest ten million euros to replace this pipeline. That certainly makes it interesting to find out whether these pipes need to be replaced completely, or whether it concerns only a part’.

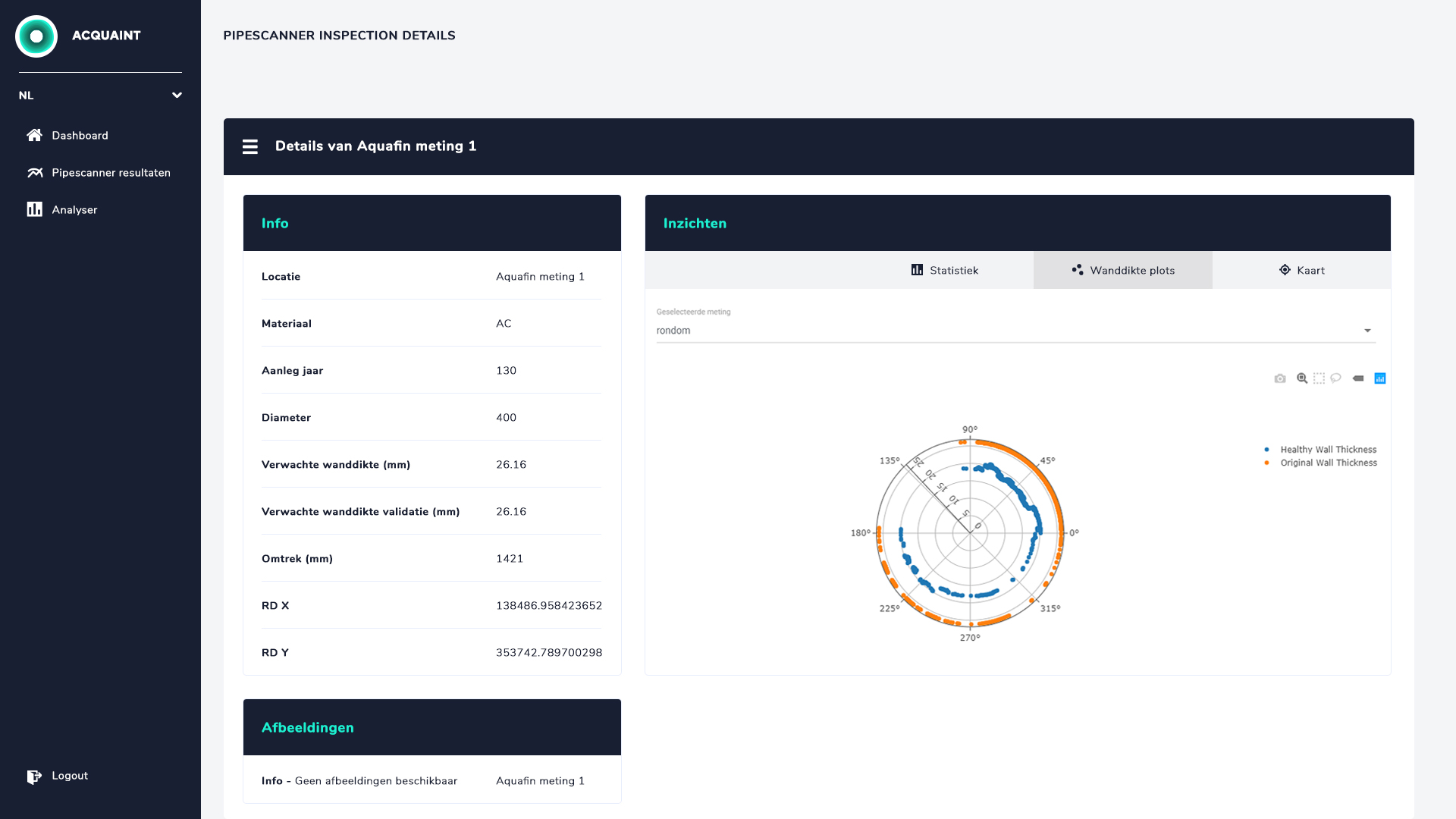

The task: inspecting a DN700/DN800 concrete pressure pipeline, part of which includes cast iron, GRP and ductile iron. For this job, the Acquarius, a PIG (Pipeline Inspection Gauge), was the best tool to use. This is because the Acquarius measures many different properties of the pipeline. For example, it uses ultrasonic sensors to determine the wall thickness, axial deformation, and the condition of the joints (angular rotation/joint widths) of the pipe. These sensors can also measure deviations in the pipeline such as the tangential deformation (ovality) of the PVC pipe sections. Through our MFW sensor, wire breaks in prestressed concrete pipes can also be detected. Furthermore, the Acquarius also contains advanced inertial sensors (IMU) that determine the location of the route in State Triangle coordinates.

Verkuijlen was also convinced that it was the right choice to use the Acquarius to inspect the pipeline: ‘This tool immediately provides all the insights needed to determine the technical condition and the technical residual life. There are other companies that say they can provide the same insights, but they often combine several tools. Currently, there are no other companies that can provide WBL with the information like Acquaint does with the Acquarius.’

The Acquarius immediately provides all the insights needed to determine the technical condition and the technical residual life

Frank Verkuijlen

The Acquarius produced a full inline condition assessment of both pipelines. The inspection resulted in a report that gave an accurate picture of the pipeline condition and also identified any risks. The water board’s pipeline data (year/location/wall thickness/supplier) can be used to determine whether any angular displacement or gap width is exceeding the supplier’s prescribed tolerances. Or if there is presence of leaching (through highly accurate ultrasonic inspection) or deterioration in the pipelines due to H2S, signs of reduced wall thickness.

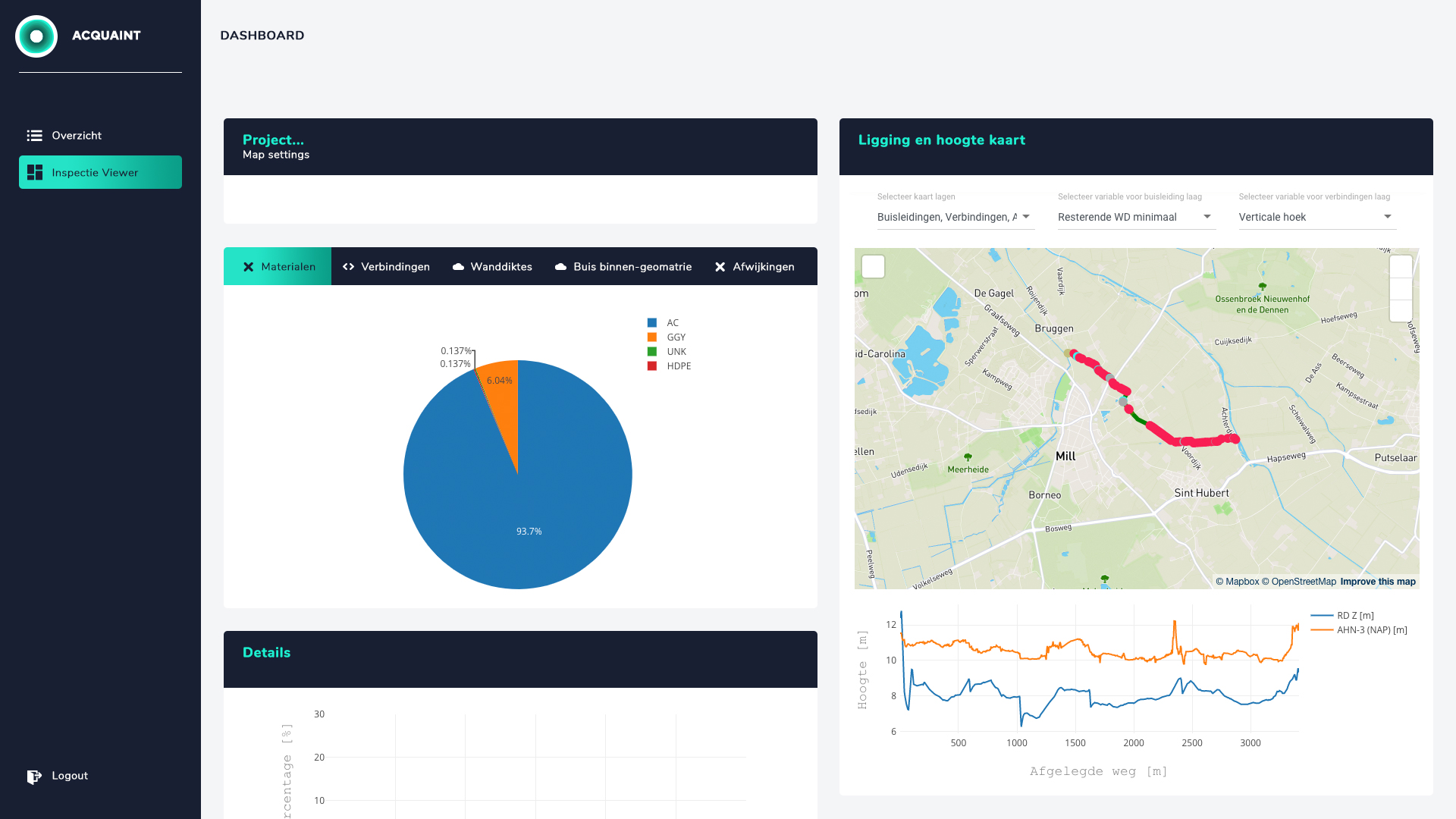

An online dashboard provides access to the reports and insights. In the course of two years, these analyses and reports have gradually improved, step by step. Bergman: ‘Reading all the data was a challenge in the beginning, especially because everything was tracked through different programs. In the meantime, all the data is collected in one environment. A single mouse click is enough to display specific data and then generate various reports. The dashboard also contains an overview of the locations that are in need of attention.’

During the past period, Acquaint has inspected a total of 45 kilometers of pressure pipelines for WBL and a further 90 kilometers will be added in the future. During the first part of the assignment, a very clear picture emerged of what did and did not need to be replaced.

Of the pressure pipelines that had already been inspected (45 kilometers), the use of the Acquarius showed that only 20% needed to be replaced because they had theoretically collapsed. This involved pipeline material affected by H2S and leaching. However, this means that about 80% of the pipelines do not need to be replaced, which initially, based on a theoretical approach and desk study, had been assumed to also need to be replaced. Here lies the power of absolute condition data, which is and remains necessary to make good predictions.

Before the inline inspection could be carried out, the necessary preparatory work had to be done. Furthermore, it is very important that during the entire preparation and execution of the inline inspection the transport of the wastewater is not interrupted for too long, causing overflows of the untreated wastewater.

‘In order to do this type of inline inspection, it is important that prior to the project, a number of issues are first identified, these being:

This requires a proper preparation’, says Verkuijlen.

Acquaint’s inspection results provided WBL with the insights they were asking for. In a few places, the pipeline was several feet from its expected location, but this did not cause any problems. In general, everything looked very well. No deterioration had been found that could cause leaks and the rest of the technical life still largely fulfilled the required pipeline integrity.

‘Thanks to the data we have obtained, we can now reliably determine where maintenance is needed and where the pipelines are still good. As a result, we can postpone the replacement task in certain places by as much as thirty years! That is very valuable information to have, because it allows us to work more efficiently, but especially because we are spared a lot of unnecessary expenses’, says Verkuijlen.

WBL sees Acquaint as more than a supplier. Verkuijlen explains: ‘It is not a party that only carries out an assignment in return for payment. They are more than that. We truly see Acquaint as a partner who, together with us, will map out the unacceptable risks in our pipelines and what the actual technical condition of the pressure pipelines is’.